The Beginning

First Light is a term that refers to the earliest light emitted when the first galaxies were born. The first light occurred long after the Big Bang happened. The Big Bang occurred roughly 15 billion years ago, but the Universe was dark until the first light came millions of years after the Big Bang, after the smooth distribution of matter following the Big Bang coalesced into clumps, eventually forming galaxies...

First Light is also the term for the very first time one looks through a telescope- the first time light from the distance is magnified through a telescope.

FirstLight is what I’ve named my first telescope project, a 16 ½” primary objective Dobsonian, chosen since it is my first built telescope.

After taking John Dobson’s telescope making class the Fall of 2006, I decided to start big and to build a very large telescope. Most in the class built 8" – 12” telescopes. The mirror blank was John Dobson’s last 16 ½” at his house near the beach in San Francisco. The blank I started with was a 16 1/2" diameter by 1" thick piece of porthole glass which used to be in a ship's window. Now it will be my window to the stars!

Project Elements

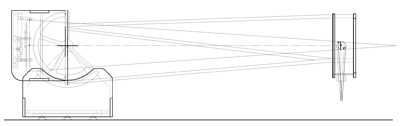

The three main elements of a truss-tube Dobsonian are the Rocker Box- the base which swivels and supports the Mirror Box by the Altitude Bearings (which allow angular elevation movement). The Mirror Box also supports the Upper Tube Assembly (UTA) with the truss tubes.

Project Details

Rocker Box: Kahya Mahogany veneered apple-ply plywood with integrated altitude and azimuth degree indicators with etched Plexiglass and illuminated with red LEDs, dimmable.

Mirror Box: Welded steel tube Mirror Cell supporting custom CNC cut aluminum triangles and bars to support and optically adjust (center) the optics, with integrated cooling fan for the mirror to reach ambient temperature. 16 1/2" diameter primary mirror, hand ground and polished. Teflon and ebony star laminate altitude bearings.

Truss Tubes: Structurally sized with assistance from Structural Engineer friends 3d model, 1 1/2" OD aluminum tubes.

UTA: 1800Destiny three vane curved spider with modified adjustors to hold the secondary mirror. MoonLite focuser on custom etched Plex board (signed by John Dobson, the telescope-making guru himself)! Finder scope and laser finder boards.

Overall, when pointed at zenith, the telescope stands at just over 9 feet tall. Above a certain angle, a ladder is needed to reach the eyepiece at the top. All of the elements are sized to be balanced- essentially so when you move the telescope to position, when you release it is stable. A large portion of the design is balancing the elements to minimize weight. The optics determine size, the parts weight and distance from the balance point (the center of the Altitude Bearings) determine the balance.

Project Process

The project involved utilizing many tools and skills.

The mirror was hand ground and polished which is quite and endeavor considering it's my first one!

Software involved design in Autodesk's AutoCAD and Revit, 3d Structural analysis software, specific programs for sizing optics and other telescope specific parts (Plop for the Mirror Cell, SEC for sizing the secondary, and a couple more). Plywood and aluminum parts were CNC'd by Frank. Frank is the ShopBot at my friend's shop- Because We Can. Custom laser-cut parts were fabricated and integrated with lighting and other elements. Many processes were practiced: welding, grinding, tube cutting, tap and die set, routing, sanding, drilling, soldering/wiring, and much more went into the finished project!

The vast majority of this project is custom hand made and fabricated, using as many technical tools I could find! The aftermarket parts are seamlessly integrated into the design.

Sharing, Etc.

This spring, you can find me with FirstLight at Star Parties sponsored by the San Francisco Amateur Astronomers on Mount Tam!

Also I recently received word my project will be exhibited at the 2010 Maker Faire! I recently purchased a solar filter and hope to integrate it into the telescope to offer solar viewing at the event!